30TH ANNUAL IRONWORKER INSTRUCTORS TRAINING PROGRAM-NEW COURSES

Registration must be completed and returned to the National Training Fund office no later than June 1, 2014.

For more information go to www.ironworkers.org. Click on “Training” and then the link for the annual instructor training program.

Courses Available include:

Advanced Layout and Total Station Training (SDC19)

Prerequisites: This course is by invitation only, if interested contact Ray Dean in the DOAMM at (847) 795-1710. Operating Layout Instruments (SDC3) or experienced in layout, and completion of self-study of Mathematics for Ironworkers course including passing online unit assessments which must be completed prior to June 1, 2014. This 40-hour course is designed to prepare instructors to use drawings, apply principles of trigonometry and the Cartesian coordinate system to program, and operate a total station. Participants must be competent at reading drawings, doing layout work using an auto level and theodolite, and be able to apply the principles of trigonometry to construction layout. Participants will receive a copy of the new Advanced Layout and Total Station Training for Ironworkers training package so that they can teach this important course at their training center. Participants must bring a Construction Master Pro Trig calculator (Model 4080 V3.1) available from Calculated Industries (ordering information is posted under the math and layout sections of our bookstore.

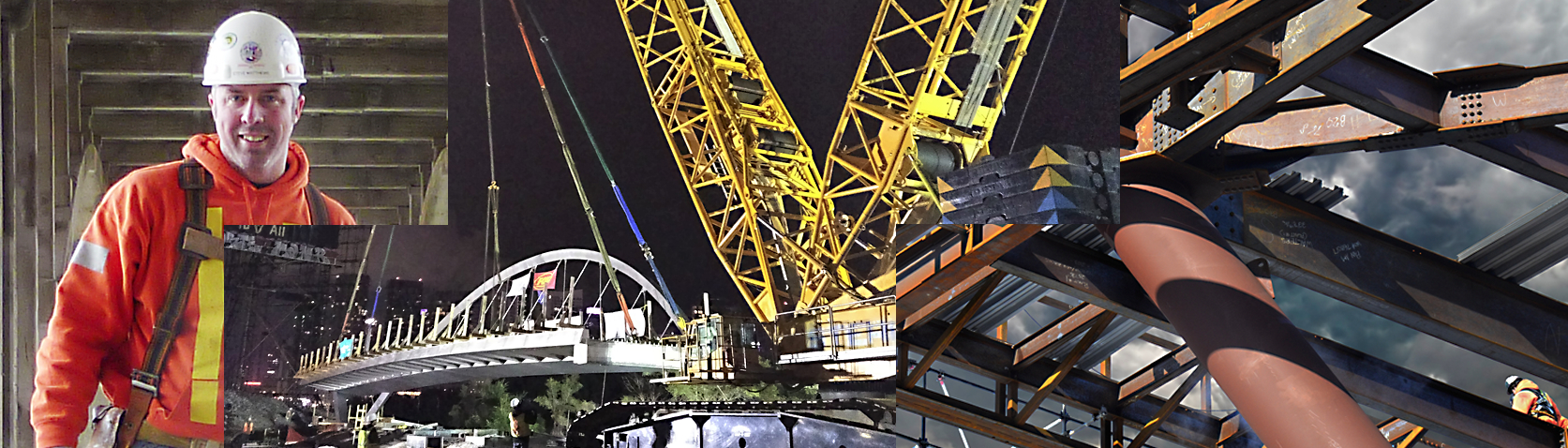

INSTRUCTORS: Gene Matthews with Keith Lantz and Carl Singleton (Leica Geosystems, Inc.)

Superintendent Training for Ironworkers (SDC20)

Prerequisites: Previous experience as a general foreman or superintendent, completion of or experience with teaching the Foreman Training course, and completion of the Level 1 Superintendent Training online course prior to the end of June (participants will register for the online component through their Apprenticeship Coordinator using the Apprentice Tracking System). This 20-hour Superintendent Training for Ironworkers train-the-trainer course is designed to develop local union instructors who can conduct this course. During this blended learning course (combination of self-study, online exercises, and group-based training) the participants will learn the roles and responsibilities of the superintendent as well as how to manage project schedules, information, people, the job site and safety. Participants will also learn communication skills, how to close out a project, and basic construction finance and law. Participants will also learn how to conduct this course at the local level.

INSTRUCTORS: Joe Werbeck and Clint Knowlton

Bidding and Contractor Competitiveness (SDC21)

This 10-hour course is designed to prepare ironworker instructors to provide an eye opening experience regarding contractor competiveness for their apprentices. Participants will learn to teach their apprentices the basics of how to estimate and then bid a project. This course will also focus on how to add in all of the hidden costs that most apprentices do not realize that contractors must deal with. Learn about the factors that impact making a profit and find out how much profit your contractor is really making. Course participants will receive a set of materials they can use to conduct an interactive, small-group, 4-hour estimating and bidding orientation for their apprentices.

INSTRUCTOR: Seth Gorman

Stainless Steel Welding and Certification (WEL10)

This 20-hour course is designed to provide updates in Stainless Steel welding along with proper techniques to ensure sound welds using SMAW and FCAW processes. This course will be taught by representatives from Miller Electric Mfg. Co., Hobart Brothers and the Iron Workers National Fund who hold CWI and CWE certifications from the American Welding Society. Participants will be given the opportunity to test to various SMAW welding procedures. Upon successful completion of each test, participants will receive a corresponding certificate and identification card from the Ironworker’s National Welding Certification Program. Participants who are certified welders will learn advanced inverter technology, troubleshooting tips and techniques for welding stainless steel. The course will include classroom instruction and hands- on training. Participants must wear appropriate work clothes for hands-on welding (including long sleeve shirts).

INSTRUCTORS: Rex Hardman, Mike McDonald, Todd Anderson, Michael Blakeman, Brian Colombo

CWB Inspector Level 1 Course (WEL11)

Prerequisites: This course is limited to Canadian members only This 76-hour Canadian Welding Bureau (CWB) course is the first step towards a new career path in visual inspection to help meet the increased demand for skilled welders due to mega- projects nationally and internationally. Topics covered in this course include:

Welding Health & Safety Basic Joints

Blueprint Reading Symbols for Welding

Welding Processes & Equipment Electrodes and Consumables

Basic Metallurgy and Material Specifications

Weld Faults and Causes Basic Inspection

Technology Codes and Standards Functions of the Inspector

Techniques of Visual Inspection

The objective of this course is to provide an educational experience specifically around the inspection requirements under CSA Standard W178.2 and is designed for clients seeking to enhance their skills and knowledge of the latest metallurgy, inspection and testing techniques.

Requirements for the course include:

Minimum 1 year of welding or inspection industry experience

At least 18 years of age

The following materials are required for this course (instructions for acquiring these materials

will be sent to those registered for the course):

CWB Modules 1-4, 6, 8, 10, 11, 13, 15, 16

CSA W178.2-08 Certification of Welding Inspectors

CSA W47.1-09 Certification of Companies for Fusion Welding of Steel – 2009

CSA W59-03 Welded Steel Construction (Metal Arc Welding)

INSTRUCTORS: William Eccles and Albert Wadden

Oxy-Fuel and Hand Plasma Cutting and Gouging (WEL 12)

This 20-hour course covers in detail the safe and proper use of Oxy-fuel and Hand plasma cutting equipment for both cutting and gouging applications. The course highlights the theory and science of the hand held plasma and oxy-fuel process but places most emphasis on the practical everyday use in the field. The course entails specialized training by representatives of ESAB that are experts in the use of hand held plasma and oxy-fuel cutting and gouging. Heavy emphasis is placed on all phases of safety during proper set up, operation and shut down.

There is also focus on selecting the right equipment for the job or application. In addition to standard practical use, we will be adding instruction on how to use cutting accessories to do plate edge beveling and prep by using simple tractor type mechanized cutting systems. Students will be given an instructor’s manual, commented copies of presentations and supporting CD-ROM’s. The course is 50% classroom and 50% hands-on applying the techniques learned in the classroom. A Q&A session allows for discussing actual issues encountered in the field and how to address them.

INSTRUCTORS: Doug Smith and Bob Bitzky

Precast Concrete Erection for Ironworkers (STR11)

This 10-hour course will be based on the new Precast Concrete Erection for Ironworkers training package. This course will focus on fabricating and transporting precast concrete products, general erection and safety procedures, erecting double-tee systems, erecting precast concrete wall systems, erecting precast concrete hollow core and girder slab systems, erecting precast concrete bridges and highway sound barriers, erecting tilt-up concrete panels, and reading precast concrete erection drawings.

INSTRUCTORS: Joe Hunt III and Pascal Kateme